The BFD Nightcap

Enjoy a BFD curated video this evening. We search the internet for the best new media news and entertainment videos for our readers so that they don’t have to.

Keep readingTiny Home Thursday

Enjoy a BFD curated video this evening. We search the internet for the best new media news and entertainment videos for our readers so that they don’t have to.

Keep readingThis Is Why We Don’t Toss Out Broken Microwaves

Enjoy a BFD curated video this evening. We search the internet for the best new media news and entertainment videos for our readers so that they don’t have to.

Keep readingBohemian Catsody – A Rhapsody Parody Song for Every Cat Queen and King!

Enjoy a BFD curated video this evening. We search the internet for the best new media news and entertainment videos for our readers so that they don’t have to.

Keep readingIsrael-Hamas War: Israeli Ambassador on Rising Civilian Deaths in Gaza

Enjoy a BFD curated video this evening. We search the internet for the best new media news and entertainment videos for our readers so that they don’t have to.

Keep readingThe BFD Daily Roundup

Just a brief note to readers who like to add their own contributions to Daily Roundup in the comments. This post is for family-friendly humour ONLY thank you.

Keep readingThe BFD Backchat

On Backchat, you are free to share your own stories, discuss other news or catch up with friends. To participate you’ll need to sign up for a Disqus account which is free, quick, and easy.

Keep readingToday in Rock History

Today in Rock History is a music orientated segment where we would like to encourage readers to share their thoughts and tastes in music and discuss the various aspects of any music topic.

Keep readingMore Free Speech Not Less Is Needed

If we really want to tackle the rise in hate online (which recent debates seem to suggest we do), public order legislation and the weight of…

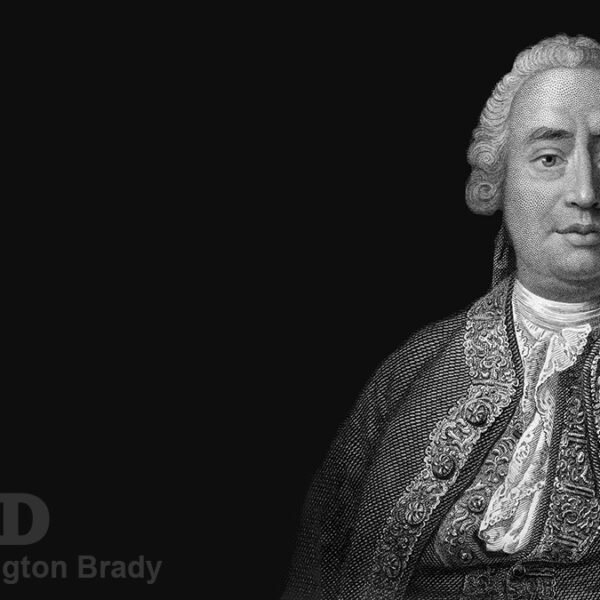

Keep readingWhy the Woke Really Hate Hume

Philosopher David Hume proved that facts don’t care about hurty feelings, 250 years ago.

Keep readingThe BFD Stuff Up of the Day

Check out the latest media stuff ups both locally and around the world.

Keep readingLaughter Is the Best Medicine

This regular daily post is the place to joke and banish negative thoughts.

Keep readingWhat Are They up to in There?

Tasmania’s “Gender Service” lurks in the shadows, away from public scrutiny.

Keep readingChristchurch Soldier Maintains Strong Family Connection With Gallipoli

Corporal Johns’ strong military heritage makes representing the New Zealand Defence Force (NZDF) at the services in Türkiye on 25 April extra significant, in particular at the Anzac…

Keep readingOne of These Things Is Just Like the Other

The toxic similarities between mandatory vaccination and fluoridation – both medical treatments forced on to the public by way of politics under the guise of science is concerning…

Keep readingIt’s off to Rwanda for You, Illegals

With an election imminent, the UK PM has an important win on illegal immigration.

Keep readingRead at Your Own Risk

The sensitive content herein is to be read at your own risk and demands a health warning. It is the duty of New Zealand Doctors Speaking Out with Science (NZDSOS)…

Keep readingA Good Government Should Not Be Afraid to Rule

The core issue with National’s Three Strikes law isn’t that it won’t work. It’s that it doesn’t go far enough.

Keep reading